The 48 V high-performance BLDC servo motor combines precision engineering with robust reliability, making it ideal for demanding motion control applications. Equipped with dual 14-bit magnetic encoders, it delivers highly accurate torque and position feedback, ensuring smooth, stable, and repeatable movements. Designed for industrial-grade performance, this motor supports multiple control modes, versatile communication interfaces, and comprehensive protection mechanisms, making it a perfect Robotic Actuator solution for robotics, automation, and research platforms.

Features

- Torque & Speed: Rated torque of 40 Nm with a peak torque of 150 Nm, ensuring high-power performance in compact applications. Rated speed: 100 rpm with a 10:1 gear ratio.

- Precision Feedback: Dual 14-bit magnetic encoders provide high-resolution, low-latency feedback for precise motion control and repeatable positioning.

- Flexible Communication: Supports CAN (1 Mbps) and UART (921600 bps) for seamless integration with controllers and automation systems.

- Multiple Control Modes: MIT mode, speed mode, and position mode allow fine-tuned motion control for diverse use cases.

- Robust Protection: Built-in safeguards against overtemperature, overvoltage, overcurrent, undervoltage, and communication loss ensure safe and reliable operation under challenging conditions.

- Durable Construction: Designed to withstand continuous industrial use, with high mechanical stability and long service life.

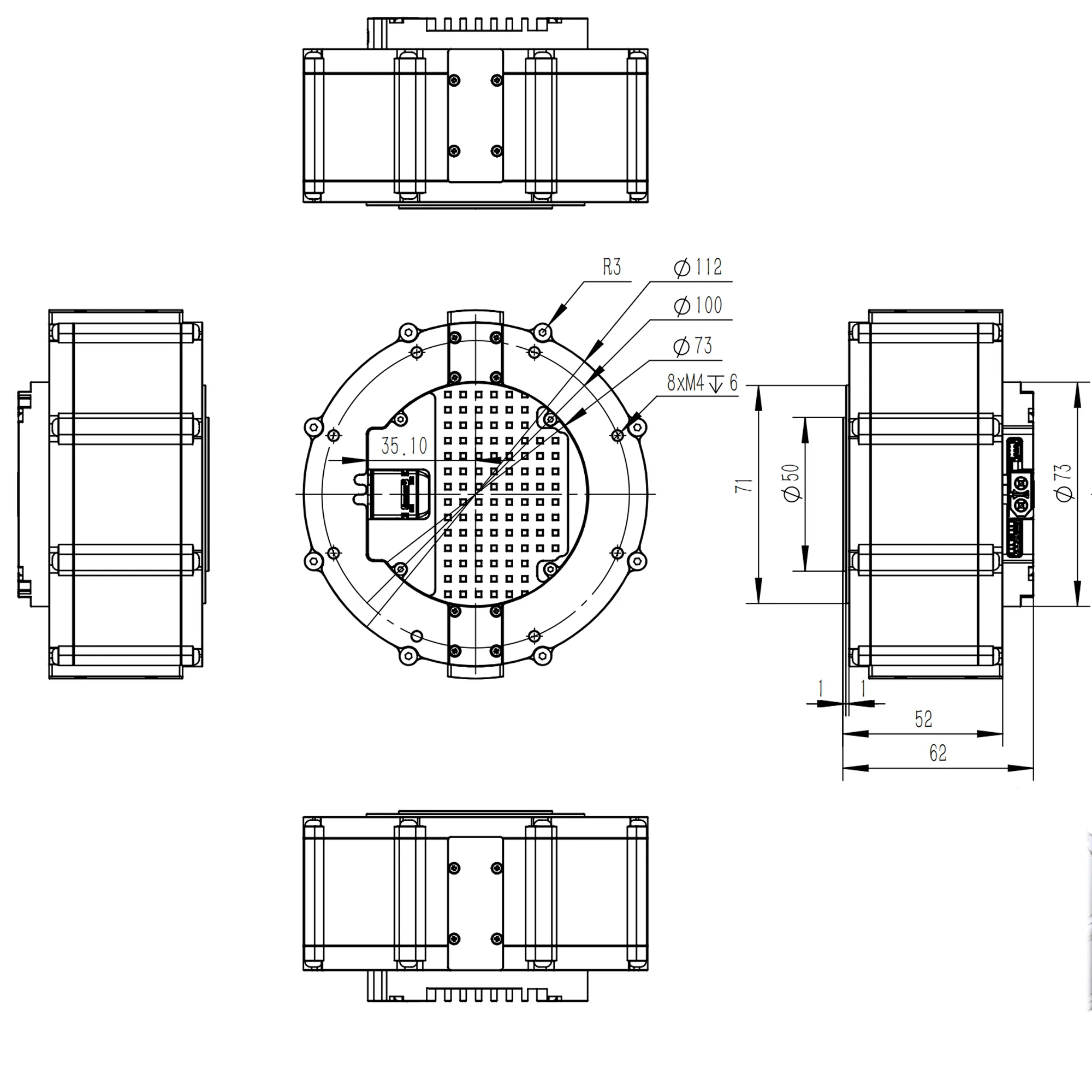

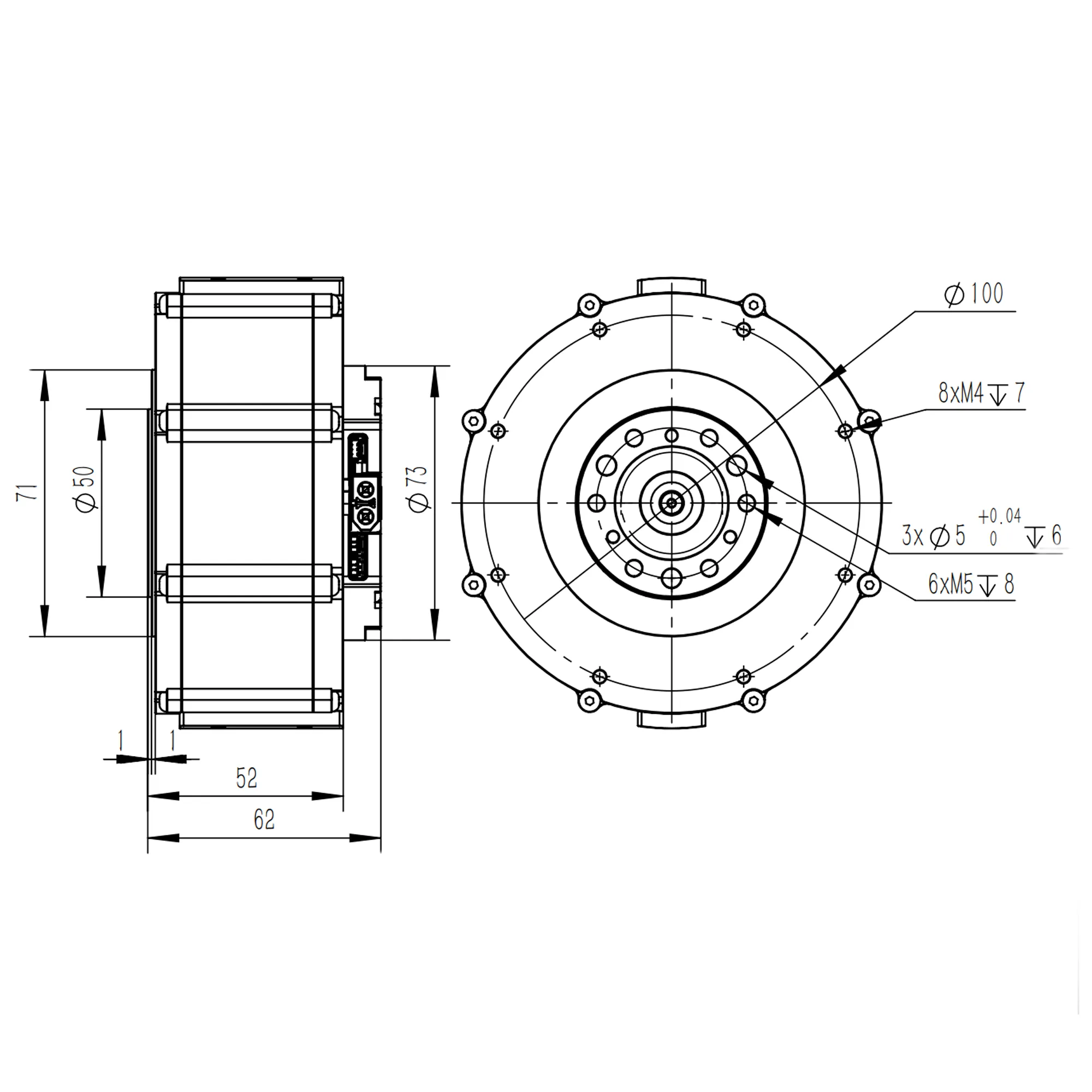

- Easy Integration: Compact design and standardized mounting options make it suitable as a Robotic Actuator for robotic arms, AGVs, and other automation systems.

Applications

- Robotics: Joints, manipulators, and collaborative robots requiring precise torque control—ideal as a Robotic Actuator.

- Industrial Automation: Actuators, conveyor systems, and precision positioning machinery.

- Mobile Platforms: AGVs, mobile robots, and autonomous vehicles.

- Medical & Assistive Devices: Rehabilitation equipment, exoskeletons, and surgical robots.

- Research & Prototyping: Advanced development platforms and experimental robotics.

- Any application requiring high-torque, accurate, and reliable motion control in a compact form factor.

Reviews

There are no reviews yet.