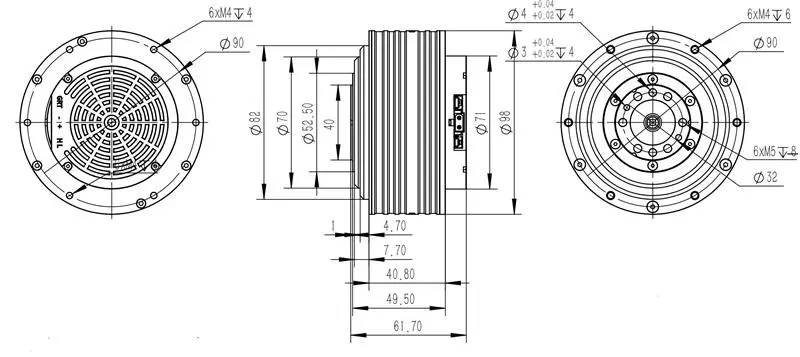

The DMBOTs DM-J8009P-2EC dual-encoder joint motor is an advanced robotic actuator designed for high-precision motion control, widely used in industrial automation and robotics. The motor features a dual-encoder system, with one encoder providing single-turn absolute position feedback, ensuring accurate position data is retained even after a power loss. Its integrated design tightly combines the driver and motor body, creating a compact smart module that saves space and simplifies installation, making it ideal for deployment in confined spaces. Supporting CAN bus communication, it can transmit important operating parameters in real time, ensuring stability and reliability in complex industrial environments. Additionally, the motor is equipped with dual temperature protection and trapezoidal acceleration and deceleration control, ensuring safety under high-load conditions and smooth motion control. This high-rigidity motor is suitable for high-precision, high-reliability applications such as robotics, automated production lines, CNC machines, and precision instruments.

Features

- Dual encoders: outputs single-turn absolute position on the output shaft, with no risk of losing absolute position even during power loss.

- Integrated motor and driver design: compact structure with high integration.

- Supports visual debugging on the host computer and firmware upgrades.

- Provides feedback on motor speed, position, torque, and motor temperature via CAN bus.

- Equipped with dual temperature protection.

- Output shaft with crossed-roller bearing: higher radial and moment rigidity, improved rotational accuracy and repeatability — ideal for demanding precision and load-bearing applications.

Application

- Robotics: industrial and collaborative robots.

- Automated Production Lines: for assembly, material handling, and testing.

- CNC Machines: precision control in machining.

- Automated Warehousing: material handling and sorting.

- Precision Instruments: medical and optical devices.

- Test Systems: automated testing and data collection.

- Aerospace and Military: spacecraft and military robotics.

Quick comparison (DM-J8009P-2EC vs DM-J8009-2EC)

- DM-J8009P-2EC: output shaft uses crossed-roller bearing — higher rigidity, better angular accuracy and load capacity for precision/oscillatory loads.

- DM-J8009-2EC: output shaft uses thin-wall deep-groove ball bearing — compact, lower weight and cost, suitable for many standard applications.

Reviews

There are no reviews yet.