The DMBOTs DM-J4340-2EC Robotic Actuator Motor is a high-performance, compact solution designed for demanding robotic applications requiring precise and reliable joint motion. This advanced robotic actuator motor integrates a brushless motor, built-in driver, gearbox, and dual single-turn absolute magnetic encoders into one module, significantly simplifying system design and reducing cabling complexity.

With a rated torque of 9 N·m and peak torque up to 27 N·m via a ~40:1 gearbox, the DMBOTs DM-J4340-2EC robotic actuator motor delivers powerful, smooth control ideal for robotic arms, cobots, humanoids, and exoskeletons. Its dual 14-bit absolute encoders provide precise single-turn absolute position feedback on the output shaft, maintaining exact position even after power loss and eliminating position drift for safe, reliable operation.

Equipped with an integrated driver supporting three control modes—position, velocity, and torque—this robotic actuator motor offers flexible and advanced control options. The CAN bus interface continuously transmits real-time motor speed, position, torque, and temperature data, and supports firmware upgrades alongside PC visualization tools for efficient debugging.

Additional features include dual temperature protection and trapezoidal acceleration/deceleration control, ensuring safety and smooth motion under high-load conditions. The integrated design, combining motor and driver tightly, saves space and eases installation—ideal for confined robotic environments and high-precision automation.

The DMBOTs DM-J4340-2EC robotic actuator motor stands out for its reliability and precision, making it a perfect fit for industrial automation, robotic research, and advanced robotics requiring high accuracy and durability.

Key Features of DMBOTs DM-J4340-2EC

- Rated torque: 9 N·m nominal; Peak torque: 27 N·m

- Built-in reduction gearbox (~40:1) for compact high-torque output

- Integrated brushless motor and driver in one compact unit

- Dual single-turn 14-bit absolute magnetic encoders on output shaft—precise position feedback, no loss after power off

- Supports three control modes: position, velocity, torque

- CAN bus communication with real-time feedback of speed, position, torque, and temperature

- Supports PC visualization and firmware upgrades

- Dual temperature protection for safe operation

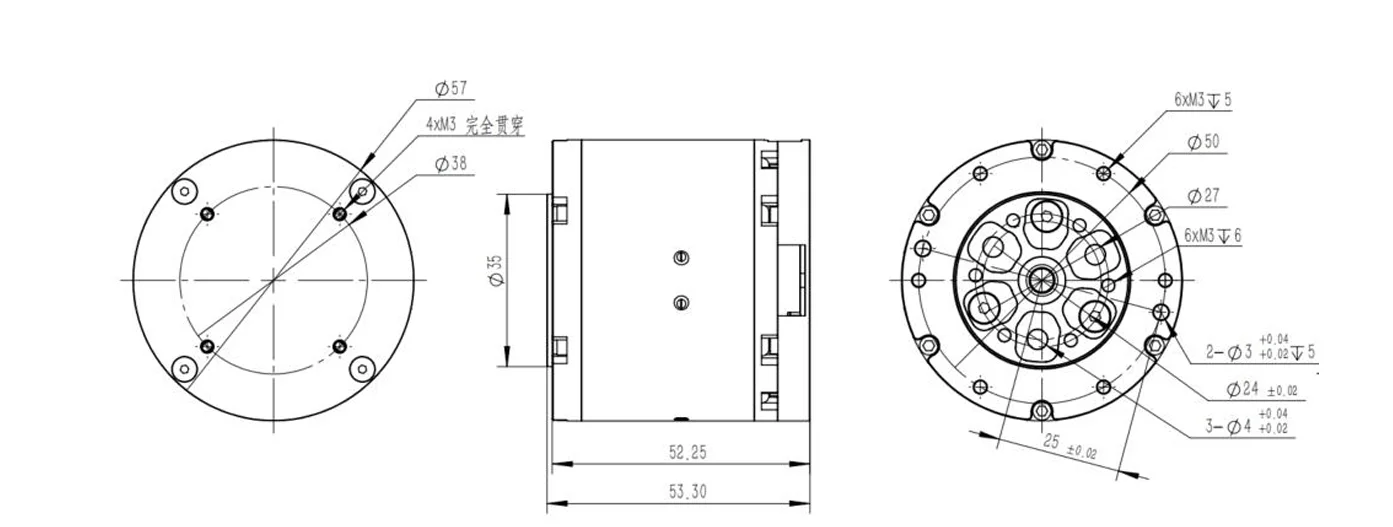

- Compact size: ~57 mm diameter, 53–56 mm height; weight: 362–375 g

Motor Dimensions and Installation

Please refer to the motor mounting hole dimensions and positions to install the motor onto the corresponding equipment.

Indicator Light Status

| Normal Status | Green On | ERR = 1, Indicates ‘Enable Mode’, normal operation |

| Red On | ERR = 0, Indicates ‘Disable Mode’ | |

| Abnormal Status | Red Light Blinking | Indicates fault, corresponding codes: |

| 8 – Over-voltage; | ||

| 9 – Under-voltage; | ||

| A – Over-current; | ||

| B – MOS Over-temperature; | ||

| C – Motor winding over-temperature; | ||

| D – Communication failure; | ||

| E – Overload |

MIT Mode

MIT mode is designed to be compatible with the original MIT mode, allowing seamless switching while providing flexible control range settings (P MAX, V MAX, T MAX). The ESC converts the received CAN data into control variables, calculates the torque value, and uses it as the current reference for the current loop. The current loop then regulates the current according to its control law to achieve the desired torque current.

Application

- Robotics: Industrial and collaborative robots.

- Automated Production Lines: For assembly, material handling, and testing.

- CNC Machines: Precision control in machining.

- Automated Warehousing: Material handling and sorting.

- Precision Instruments: Medical and optical devices.

- Test Systems: Automated testing and data collection.

- Aerospace and Military: Spacecraft and military robotics.

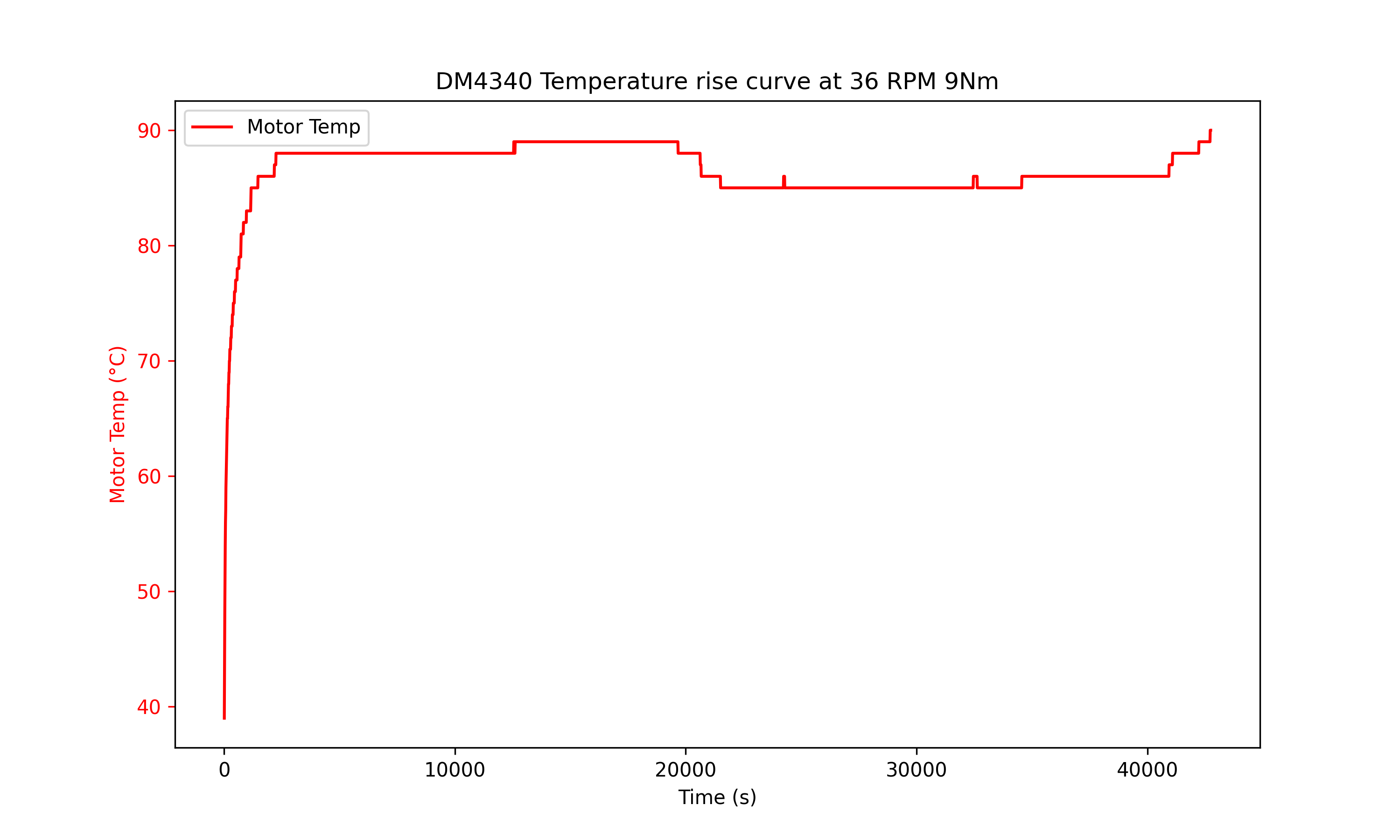

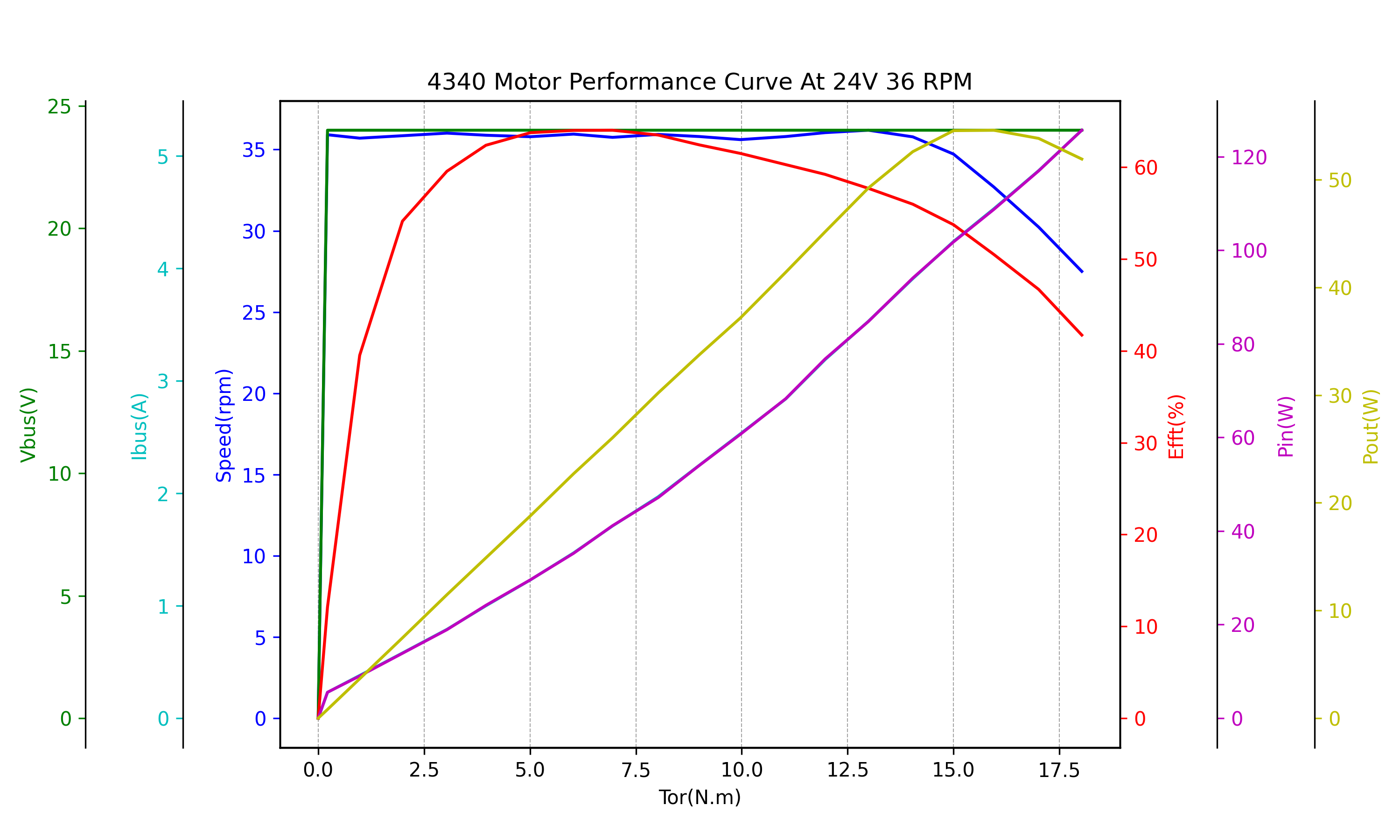

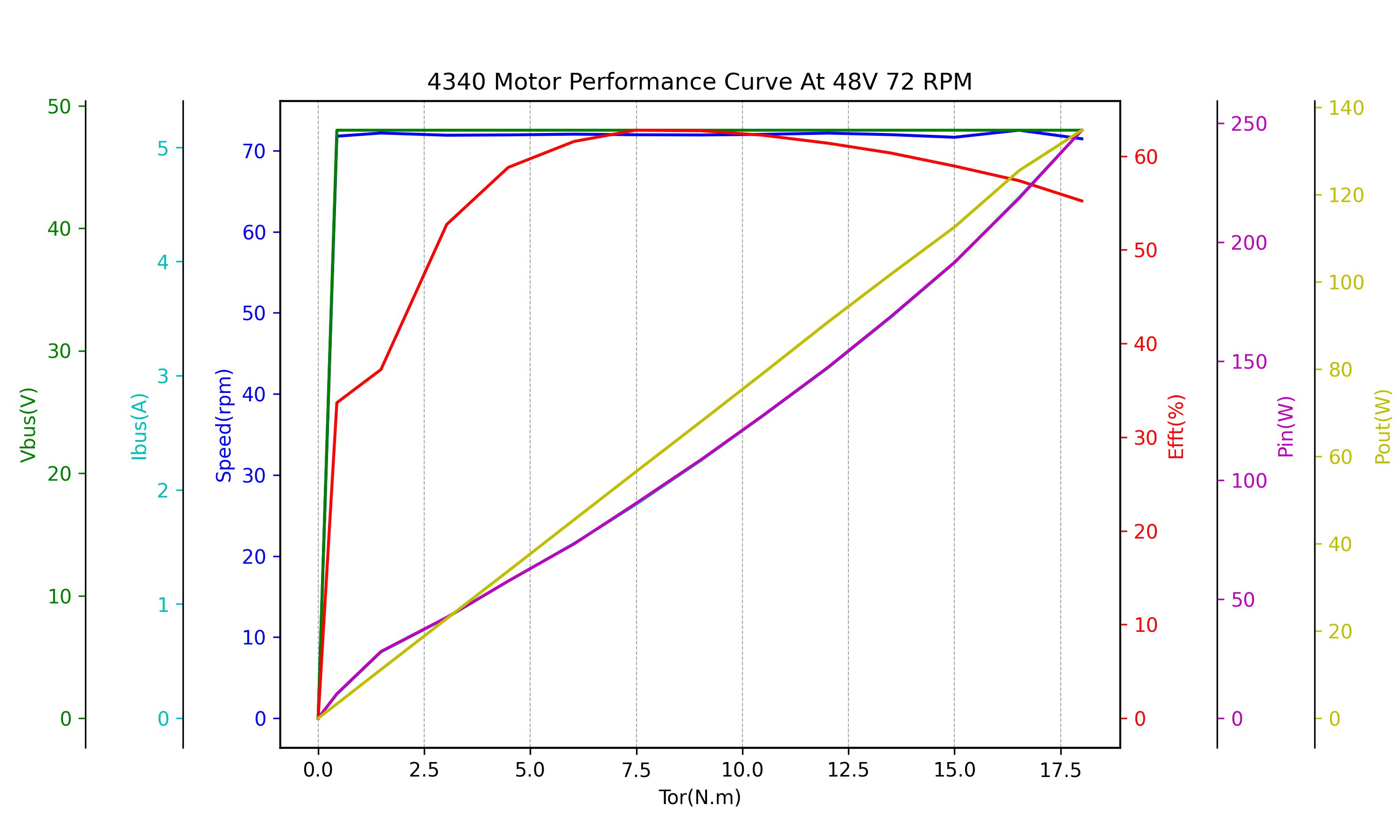

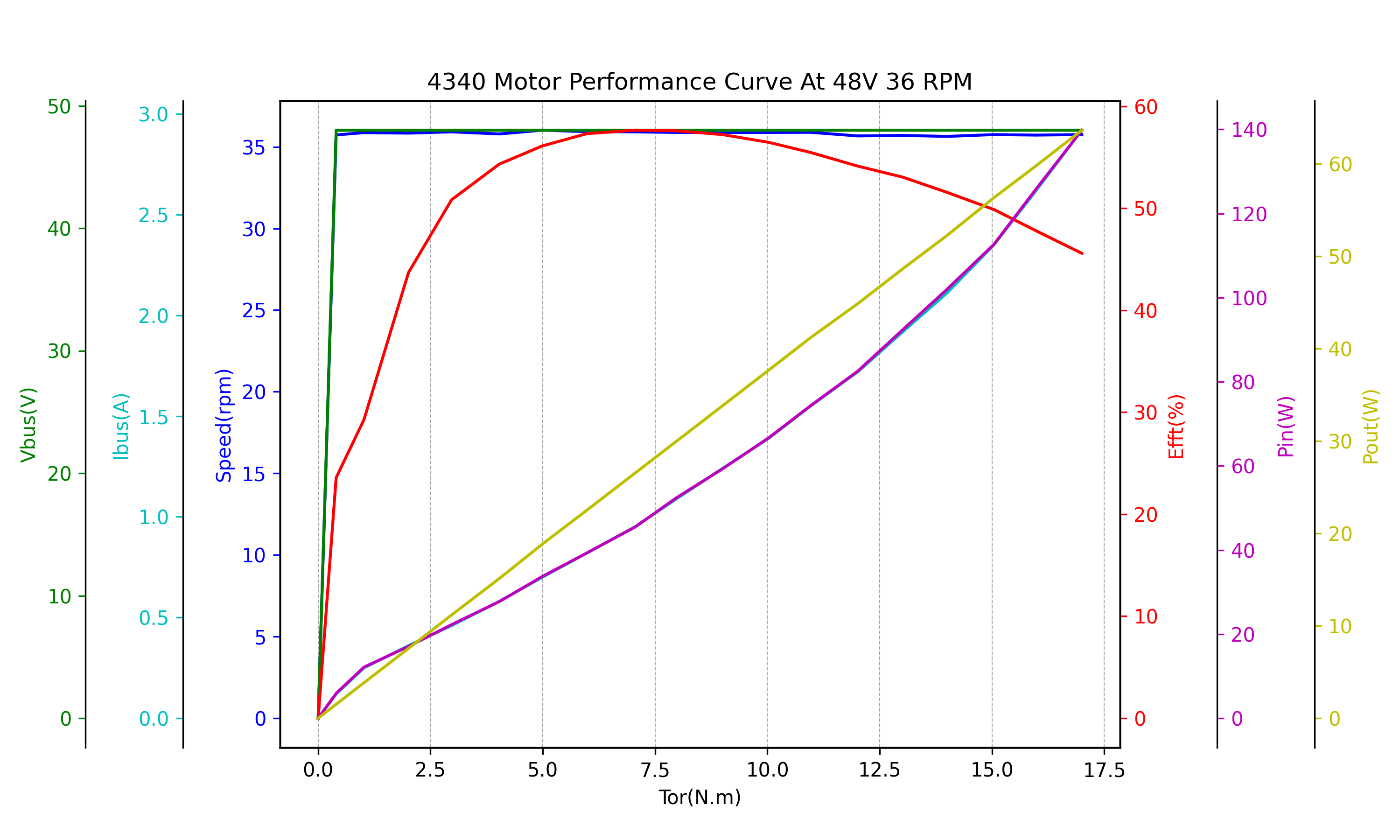

Motor Performance Curve

Temperature curve of 4340 motor at 9 Nm torque

Performance curve of 4340 motor at 24V and 36 RPM

Performance curve of 4340 motor at 48V and 72 RPM

Performance curve of 4340 motor at 48V and 36 RPM

Reviews

There are no reviews yet.