DMBOTs DM-J4340 Joint Motor

The DMBOTs DM-J4340 is a high-performance joint motor with integrated dual encoders and driver, ideal for robotic arms, cobots, AGVs, and modular robots. Featuring a compact form factor and reliable control, it supports CANopen, PWM, and serial communication. Perfect for industrial automation, education, and research environments.

DM-J4340-2EC Robotic Actuator Motor Specifications

| Parameter Category | DM-J4340-2EC (24V) | DM-J4340-2EC (48V) |

| Rated Torque | 9 Nm | 9 Nm |

| Peak Torque | 27 Nm | 27 Nm |

| No-Load Max Speed | 52 rpm | 100 rpm |

| Rated Current | 2.5 A | 2.5 A |

| Peak Current | 8 A | 8 A |

| Outer Diameter | 57 mm | 57 mm |

| Height | 53.3 mm | 53.3 mm |

| Weight | ~362 g | ~362 g |

| Encoder | Dual 14-bit magnetic encoder | Dual 14-bit magnetic encoder |

What These Parameters Mean

- 9 Nm Torque: Enough to easily drive a 5–10 kg robotic arm joint.

- 27 Nm Peak Torque: Can handle short bursts of ‘heavy-duty’ operations, like lifting a relatively heavy load.

- Dual 14-bit Encoder: Provides very high positioning accuracy, so the motor moves smoothly with almost no ‘shaking’ during motion.

Three Operating Modes – Like Switching ‘Driving Styles’

MIT Mode – ‘Smart Driving’

Example Cases

p_des = 0.0; // Position not controlled

v_des = 20.0; // Target speed = 20 rad/s

kp = 0.0; // Disable position loop

kd = 1.0; // Speed loop gain

t_ff = 0.0; // No feedforward torque

// MIT Mode Example Command

p_des = 0.0;

v_des = 0.0;

kp = 0.0;

kd = 0.0;

t_ff = 2.0; // Apply 2 Nm torque

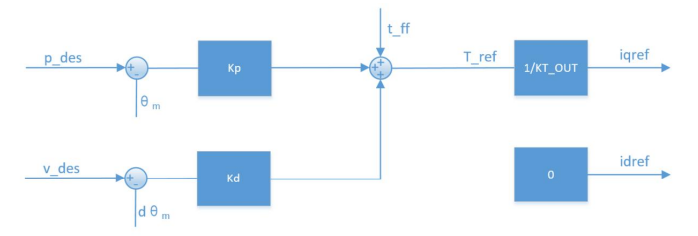

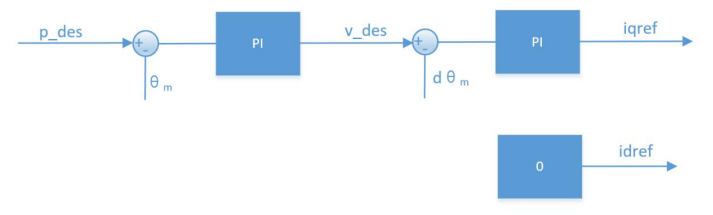

Position-Velocity (Cascaded Position) Mode — imilar to ‘Autonomous Navigation’

- The outer loop is the position loop, whose output serves as the setpoint for the velocity loop.

- The velocity loop output serves as the setpoint for the inner current loop, which controls the actual current output. The control block diagram is as follows:

p_desis the target position for control.v_desis used to limit the maximum absolute speed during motion.

p_des = 1.57 rad), but you want to limit its speed. You can set a maximum speed v_des. The motor will then reach the target smoothly following the sequence: accelerate → constant speed → decelerate.

1.57 rad) while limiting the maximum speed to 5 rad/s:

// Position-Velocity Mode Command Example

p_des = 1.57; // Target angle 90°

v_des = 5.0; // Maximum speed 5 rad/s

kp = 50.0; // Position loop gain

kd = 1.0; // Velocity loop damping

t_ff = 0.0; // No additional torque feedforward

- High precision

- Smooth motion

- Suitable for robot joint movements, e.g., slow grasping with a robotic arm

- Slightly slower response

- Not suitable for scenarios requiring ‘lightning-fast’ movements

- When using the recommended parameters from the debugging assistant, good control accuracy can be achieved and the motion remains relatively smooth, though the response time is longer.

- Besides

v_des, you can also configure acceleration and deceleration values. Increasing them may reduce oscillations during motion. - Units:

p_desin rad,v_desin rad/s, data type: float. - The damping factor must be a positive number greater than 0. For reference, see the notes for Velocity Mode.

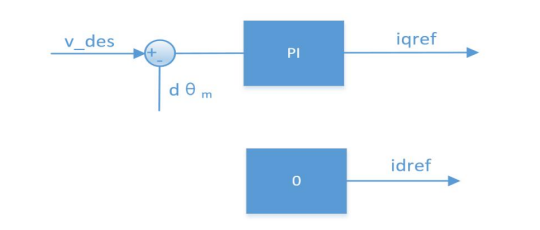

Velocity Mode — Similar to ‘Cruise Control’

- For example, if you want a wheeled robot to move continuously at 50 rad/s, you can simply set

v_des = 50, and the motor will maintain that speed steadily.

// Velocity Mode Command Example

p_des = 0.0; // Position is not controlled

v_des = 50.0; // Constant speed 50 rad/s

kp = 0.0; // No position loop control

kd = 4.0; // Damping factor, recommended value

t_ff = 0.0; // No additional torque feedforward

- The damping factor

kdshould be set between 2.0 and 10.0, with 4.0 recommended. - If too small, the motor will oscillate.

- If too large, the motion will feel sluggish.

v_desunit is rad/s, data type float.- When using the debugging assistant to automatically calculate parameters, the damping factor must be a positive number greater than 0.

- A too-small damping factor may cause speed oscillation and overshoot, while a too-large damping factor may increase rise time. The recommended value is 4.0.

- Maintains a stable, constant speed

- Simple and effective for tasks like wheeled robot motion

How to ‘Talk’ to the Motor: CAN Communication

- Receive Frames: Control data sent to the motor, e.g., ‘move to 90°’ or ‘maintain 50 rad/s speed.’

- Feedback Frames: Status data sent by the motor back to the controller, e.g., ‘I’m at 45°, my speed is 20 rad/s, temperature is 60°C.’

Feedback Frame

- Position (POS): Current motor angle

- Velocity (VEL): Current speed

- Torque (T): Current output torque

- MOS Temperature (T_MOS): Average temperature of the MOSFETs on the driver

- Rotor Temperature (T_Rotor): Average temperature of the motor coils

- Error Code (ERR): Status like overcurrent, overvoltage, overtemperature

| feedback message | D[0] | D[1] | D[2] | D[3] | D[4] | D[5] | D[6] | D[7] |

| MST_ID | ID|ERR<<4 | POS[15:8] | POS[7:0] | VEL[11:4] | VEL[3:0]|T[11:8] | T[7:0] | T_MOS | T_Rotor |

- ID indicates the controller ID, taking the lower 8 bits of the CAN_ID.

- ERR indicates the status, corresponding to the following types:

- 0 — Disabled

- 1 — Enabled

- 8 — Overvoltage

- 9 — Undervoltage

- A — Overcurrent

- B — MOS Overtemperature

- C — Motor Coil Overtemperature

- D — Communication Lost

- E — Overload

- POS indicates the motor position information.

- VEL indicates motor velocity information.

- T indicates motor torque information.

- T_MOS indicates the average temperature of the MOS on the driver, in ℃.

- T_Rotor indicates the average temperature of the motor’s internal coil, in ℃.

- The position uses 16-bit data.

- Velocity and torque both use 12-bit data.

- Temperatures are in °C

Control Frames

MIT Mode

| control message | D[0] | D[1] | D[2] | D[3] | D[4] | D[5] | D[6] | D[7] |

| ID | p_des [15:8] | v_des [11:4] | v_des[3:0]| Kp[11:8] | VEL[3:0]|T[11:8] | Kp [7:0] | Kd [11:4] | Kd[3:0]| t_ff[11:8] | t_ff[7:0] |

- ID equals the set CAN ID value.

- P_des: desired position

- V_des: desired velocity

- Kp: position proportional gain

- Kd: position derivative gain

- T_ff: desired torque

- Position uses 16 bits (2 bytes)

- Velocity uses 12 bits

- Kp uses 12 bits

- Kd uses 12 bits

- If CAN ID = 0x01, and you want the motor to move to a certain position with a specific velocity and torque, you would encode these five parameters into the 8-byte frame according to the bit allocation above and send it via the CAN bus.

Control Frame in Position-Velocity Mode

| control message | D[0] | D[1] | D[2] | D[3] | D[4] | D[5] | D[6] | D[7] |

| 0x100+ID | p_des | v_des | ||||||

- Frame ID: the set CAN ID plus an offset of 0x100.

- P_des: desired position, in floating-point format, low byte first, high byte last.

- V_des: desired velocity, in floating-point format, low byte first, high byte last.

- Velocity here represents the maximum speed during trapezoidal acceleration, i.e., the speed in the constant-speed segment.

- Suppose your motor’s CAN ID is

0x01. - The control frame ID for position-velocity mode will be

0x101(0x100 + 0x01). - If you want the motor to move to position

100.0with a maximum velocity of50.0, you encodeP_des = 100.0andV_des = 50.0into the CAN frame (low byte first, high byte last) and send it to ID0x101.

Control Frame in Velocity Mode

| control message | D[0] | D[1] | D[2] | D[3] |

| 0x200+ID | v_des | |||

- Frame ID: the set CAN ID plus an offset of 0x200.

- V_des: desired velocity, in floating-point format, low byte first, high byte last.

- Suppose your motor’s CAN ID is

0x01. - The control frame ID for velocity mode will be

0x201(0x200 + 0x01). - If you want the motor to run at a speed of

50.0units/s, you encodeV_des = 50.0into the CAN frame (low byte first, high byte last) and send it to ID0x201.

Practical Example

- Use a USB-CAN tool and set the baud rate to 1 Mbps.

- Send a control frame:

- CAN ID:

0x01(assuming motor ID = 1) - Data: pack

P_des,V_des,Kp,Kd, andT_ffinto the 8-byte frame.

- If the motor shakes or vibrates, check the damping (Kd) and maximum speed settings.

- Watch the temperature to avoid long-term overload and overheating.

How to Debug a Motor: Check It Like a ‘Health Check’

- Power: Connect a 24V or 48V power supply using an XT30 connector.

- Communication: Connect the CAN interface to your computer.

- Serial port: Use a GH1.25 3-pin cable to connect to the PC.

- If the motor feels too ‘aggressive’ when starting, you can reduce the acceleration parameter in the Debug Assistant. The motor will then rotate more smoothly and gently.

- Power: 24V/48V → XT30 connector

- Communication: CAN H, CAN L → USB-CAN → Computer

- Open Damy Debug Assistant → Select port → Connect

- Click ‘Real-Time Monitoring’ to see:

- Motor speed

- Temperature curves

- Torque changes

50 rad/s. The motor will run at its maximum speed, and you can see the real-time curves on the interface.Motor Safety and Protection Features

- Driver Over-temperature Protection: triggers at 120℃; if exceeded, the motor exits ‘enable mode’.

- Motor Over-temperature Protection: adjustable based on usage; recommended not to exceed 100℃. Exceeding this will also exit ‘enable mode’.

- Over-voltage Protection: adjustable based on usage. Recommended limits:

- 24V motor: ≤32V

- 48V motor: ≤52V Exceeding these values will exit ‘enable mode’.

- Under-voltage Protection: if power supply drops below the set threshold (recommended ≥15V), the motor exits ‘enable mode’.

- Over-current Protection: adjustable based on usage; recommended ≤9.8A. Exceeding this will exit ‘enable mode’.

- Communication Loss Protection: if no CAN commands are received within the set period, the motor will automatically exit ‘enable mode’, preventing uncontrolled operation.

- Run the motor under a heavy load (e.g., hang a 5 kg weight).

- If the temperature rises toward the limit (e.g., 100℃ for the motor), the motor will automatically stop and return an error code.

- The Debug Assistant will show alerts, helping prevent damage.

How to Use the DMBOTs DM-J4340 Joint Motor

- Hardware SetupConnect a 24V or 48V power supply.

- Connect the CAN bus to your controller or PC.

- (Optional) Use a serial cable for monitoring.

- Software Setup

- Install the DMBOTs Debug Assistant.Open it, select the correct port, and connect.

- Set parameters like position, speed, and torque.

- Operation Modes

- Position Mode: precise joint movement

- Speed Mode: control motor speed

- Torque Mode: control output force

- Testing

- Run the motor and watch the feedback in the software (position, speed, temperature).

- Adjust parameters as needed.

- Safety Protections

- Over-temperature, over/under-voltage, over-current, and communication loss protections automatically stop the motor to prevent damage.

DMBOTs DM-J4340-2EC Robotic Actuator Motor

- Want smooth motion or precise robotic joints? Use Position-Velocity Mode.

- Want stable speed or to drive a wheeled chassis? Use Velocity Mode.

- Want flexible control or to write your own code? Use MIT Mode.

Your blog is a constant source of inspiration for me. Your passion for your subject matter is palpable, and it’s clear that you pour your heart and soul into every post. Keep up the incredible work!

Your writing is like a breath of fresh air in the often stale world of online content. Your unique perspective and engaging style set you apart from the crowd. Thank you for sharing your talents with us.

helloI like your writing very so much proportion we keep up a correspondence extra approximately your post on AOL I need an expert in this space to unravel my problem May be that is you Taking a look forward to see you

Your blog is a true hidden gem on the internet. Your thoughtful analysis and engaging writing style set you apart from the crowd. Keep up the excellent work!

I have been surfing online more than 3 hours today yet I never found any interesting article like yours It is pretty worth enough for me In my opinion if all web owners and bloggers made good content as you did the web will be much more useful than ever before

Thank you for the good writeup It in fact was a amusement account it Look advanced to far added agreeable from you However how could we communicate

If you have any questions, please feel free to contact us via email. We’ll be happy to answer them, and more practical articles will be published later.

Your blog is a true hidden gem on the internet. Your thoughtful analysis and engaging writing style set you apart from the crowd. Keep up the excellent work!

Ive read several just right stuff here Certainly price bookmarking for revisiting I wonder how a lot effort you place to create this kind of great informative website

I just could not leave your web site before suggesting that I really enjoyed the standard information a person supply to your visitors Is gonna be again steadily in order to check up on new posts

Your writing is like a breath of fresh air in the often stale world of online content. Your unique perspective and engaging style set you apart from the crowd. Thank you for sharing your talents with us.

I just wanted to express my gratitude for the valuable insights you provide through your blog. Your expertise shines through in every word, and I’m grateful for the opportunity to learn from you.

Your ability to distill complex concepts into digestible nuggets of wisdom is truly remarkable. I always come away from your blog feeling enlightened and inspired. Keep up the phenomenal work!