MIT-Driven DC Brushless Joint Motor | Powerful Torque and Precision Control:

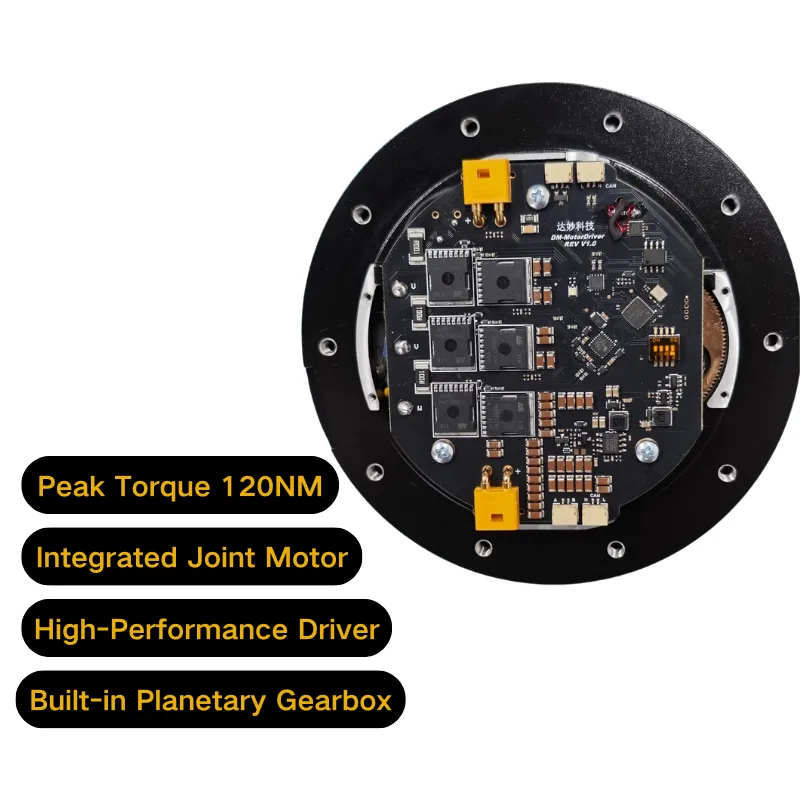

The DM-J10010L-2EC is a high-performance DC Brushless joint motor featuring an integrated planetary gearbox, dual encoders, and a peak torque of 120NM. Designed for high-precision robotics and complex motion control systems, this motor delivers exceptional stability and control performance, ensuring smooth and reliable operation even under demanding conditions.

Key Features:

- High Torque Output: 120NM peak torque, 40NM rated torque, suitable for high-load applications.

- Integrated Dual Encoders: Provides absolute position feedback for enhanced accuracy and precise positioning.

- Built-in Planetary Gearbox: 10:1 reduction ratio for optimized power output and stable, efficient motion control.

- Multiple Control Modes: Supports MIT mode, speed mode, and position mode to meet diverse application needs.

- High-Performance Driver: Optimized for smooth and stable motion in high-demand scenarios.

- Comprehensive Protection: Includes over-temperature, over-voltage, over-current, and communication loss protection for improved safety and longevity.

- Wide Compatibility: Supports CAN communication, allowing seamless integration into control systems and external devices.

- Easy Debugging: Equipped with a USB to CAN interface for quick debugging and parameter adjustments via software tools.

- Compact Design: Integrated motor and gearbox for efficient space utilization, suitable for precision mechanical structures.

The DM-J10010L-2EC MIT-Driven DC Brushless joint motor is ideal for robotics, industrial automation, and humanoid machines, enabling more precise and efficient motion control.

Interface and Pinout Description:

| Specific Name – Serial Number | Description |

| Power Connection Interface – 1 | 1. Connect to the power supply through an XT30 male – to – female power cable. The rated voltage is 24V (supports 24 – 48V) to supply power to the motor. |

| Power Connection Interface – 2 | 2. The motor has two power connection interfaces. Either interface can be used alone, or multiple motors can be connected in series for convenient cabling. It is recommended that the number of series – connected motors does not exceed 2. |

| CAN Communication Terminal – 1 | 1. Connect to external control equipment via CAN communication terminals, which can receive CAN control commands and feedback motor status information. |

| CAN Communication Terminal – 2 | 2. The motor has two CAN communication terminals, and either interface can be used. |

| Debugging Serial Port – 1 | Connect to a PC through a GH1.25 three – pin cable, using a USB – to – CAN debugging tool (or a general – purpose USB – to – serial module). Use the Miaoke Technology debugging assistant to configure parameters for the motor and perform firmware upgrades, etc. |

| Terminal Resistance DIP Switch – 1 | 3——485 120Ω terminal resistance |

| 4——CAN 120Ω terminal resistance | |

| 1, 2 are reserved and not in use for now. | |

| RS485 Communication Terminal – 1 | RS485 communication is not available for use yet. |

| RS485 Communication Terminal – 2 |

Applications:

- Robotics: Ideal for humanoid robots, robotic arms, and other motion control systems.

- Industrial Automation: Perfect for precise control in automated systems requiring high torque and reliability.

- Prototyping and Testing: Suitable for experimental setups where precise motion and control feedback are needed.

- Mechatronics Projects: Can be used in advanced mechatronics designs requiring high torque, speed control, and integrated feedback systems.

Reviews

There are no reviews yet.